Understanding Foam in Concrete Construction

Foam has become an essential material in modern concrete construction due to its versatility, precision, and performance. As a construction professional, you’ve likely encountered the need for void creation, block-outs, or temporary molds. Foam, particularly EPS and XPS, offers a practical solution that simplifies these tasks while improving overall construction efficiency.

At The Foam Company, we work with civil engineers, contractors, and builders every day who need reliable, cost-effective forming materials. Foam allows for the creation of complex shapes, intricate voids, and formwork that would be far more labour-intensive with traditional materials like timber or metal.

Some of the main applications where foam excels include:

- Creating accurate block-outs for plumbing and electrical pass-throughs.

- Building formers for lift shafts, beam pockets, and staircases.

- Constructing complex architectural molds and expansion joints.

- Supporting temporary structures and shaping concrete for bridge decks or infrastructure builds.

Foam’s lightweight nature makes it especially beneficial on sites where weight limitations exist, such as high-rise buildings or structures lifted by cranes. And thanks to CNC technology, every piece can be custom cut to match design drawings with millimetre precision.

Both EPS (Expanded Polystyrene) and XPS (Extruded Polystyrene) come in a range of densities, offering varying levels of compressive strength and moisture resistance. Choosing the right foam density H-grade for standard applications, VH-grade for heavy-duty applications is critical for load tolerance and pour integrity.

Understanding the role foam plays in construction can help you:

- Streamline site preparation and reduce formwork costs.

- Prevent delays by using weather and moisture resistant materials.

- Increase site safety through easier handling and fewer heavy materials.

- Deliver projects with greater accuracy and fewer on-site modifications.

In the sections below, we’ll explore the types of foam available, how density impacts performance, and why foam is preferred across civil, commercial, and residential projects.

What Are Block-outs & Formwork in Concrete?

Block-outs are intentional voids or spaces left within a concrete pour to allow for future installations such as pipes, ducts, or structural elements. Formwork, on the other hand, refers to the temporary or permanent molds into which concrete is poured to set into a desired shape.

In practical terms, block-outs and formwork are essential for:

- Utility Access: Creating space for electrical and plumbing systems.

- Structural Design: Forming beams, footings, or lift cores.

- Architectural Features: Designing recesses, window openings, or decorative elements.

Traditionally, contractors used timber, steel, or plastic to create these voids. However, these materials are often heavy, difficult to shape, and time-consuming to work with. Foam offers a cleaner, faster, and more precise alternative.

Key benefits of foam block-outs and formwork:

- Lightweight for easy handling.

- Precision-shaped using CNC technology.

- No residue or bonding with concrete.

- Faster to install and remove post-pour.

Role of Foam in Construction Voids & Inserts

Foam plays a crucial role in creating construction voids and inserts that facilitate post-pour utility integration or structural flexibility. These foam forms are used during the pouring phase and either remain embedded in the structure or are removed afterward, depending on the design.

Key roles foam serves include:

- Void formation for MEP services: Pipes, conduits, HVAC ducting.

- Creating lift shaft pockets, stairwells, and utility trenches.

- Reducing concrete volume in areas where structural material is not needed.

Civil engineers particularly value foam for its consistency and ability to meet detailed specifications. Whether it’s for bridge decks or internal floor slabs, foam inserts allow for:

- Smooth, uniform surfaces post-pour.

- Reduced need for post-pour drilling or chiseling.

- Improved scheduling by pre-planning utility runs.

Using high-density EPS or XPS foam ensures the form holds its shape under the pressure of wet concrete, minimizing the risk of deformation. This is critical in large pours or deep forms where weight and fluid pressure are high.

At The Foam Company, we offer pre-cut and CNC-profiled void forms tailored to your project needs, ensuring accuracy, durability, and code compliance.

Temporary vs Permanent Foam Forming Applications

One of foam’s greatest advantages in construction is its flexibility for both temporary and permanent formwork. Depending on the project requirements, foam can be used as a short-term mold that’s removed after curing, or left in place as a permanent structural element.

Temporary Forming Uses:

- Beam pockets and utility sleeves.

- Footing forms and lift shafts.

- Expansion joints need later removal.

In these cases, EPS or XPS is removed post-cure by pulling or cutting. The foam’s smooth surface allows for easy separation from hardened concrete.

Permanent Applications Include:

- Structural Insulated Panels (SIPs).

- Under-slab insulation that doubles as formwork.

- Void fill in non-load-bearing areas.

Here, XPS is often preferred for its moisture resistance and insulation value. EPS, particularly VH-grade, may also remain embedded if no exposure or breakdown risk is present.

Benefits of permanent foam forming:

- Reduces labour for removal.

- Provides built-in insulation.

- Saves cost on secondary material.

Whether temporary or permanent, the key is selecting the right foam density and type for your specific site conditions and pour requirements.

Why Foam Is Preferred Over Wood or Metal

Contractors are increasingly turning to foam as a replacement for traditional wood or metal formwork. The reasons are clear: foam offers better efficiency, accuracy, and safety all while cutting down on material waste and cost.

Key advantages over timber:

- Lighter to handle, requiring no heavy tools.

- No swelling, warping, or rotting when exposed to moisture.

- Doesn’t absorb concrete moisture, preserving form integrity.

Compared to metal:

- Easier to customize.

- No rusting or bonding issues.

- Lower cost for single-use or short-run forming.

Foam also reduces the margin for error. With CNC cutting, each piece is tailored exactly to your drawings no on-site trimming or adjustments required.

Other practical benefits:

- Less wear on tools and safer handling.

- Fewer workers are needed for setup and takedown.

- Easier transportation and storage.

When it comes to forming complex shapes, such as curved stairs or large beam block-outs, foam simply outperforms traditional materials in both speed and cost-efficiency.

Common Use Cases in Residential, Civil & Commercial Projects

Foam is now widely used across all sectors of construction, residential, civil, and commercial. Its adaptability makes it ideal for various block-out and formwork needs.

Residential Uses:

- Void forms for stairs and plumbing.

- Under-slab insulation that also serves as formwork.

- Footing block-outs for piers and pad foundations.

Commercial Projects:

- Beam and column formers in car parks or office buildings.

- Electrical trenching and lift shaft voids.

- Custom wall recesses and facade detailing.

Civil Infrastructure:

- Bridge decks and road barriers.

- Drainage channels and utility pits.

- Formwork for tunnels and underpasses.

In all these applications, foam delivers:

- Time savings through easy installation.

- Consistency in void dimensions across multiple pours.

- Reduced labour costs due to lighter material.

VH-grade EPS is commonly used in civil and commercial jobs for its high compressive strength. Meanwhile, XPS is favoured where moisture resistance or permanent installation is required.

The Foam Company offers bulk supply and custom CNC cutting for every use case, ensuring your project requirements are met with precision.

Overview of EPS and XPS Foam Types

When selecting foam for concrete block-outs and formwork, two primary types dominate the industry: EPS (Expanded Polystyrene) and XPS (Extruded Polystyrene). While they may look similar at a glance, their manufacturing processes, physical properties, and performance characteristics differ significantly and each has its ideal application depending on site conditions and load requirements.

At The Foam Company, we supply a full range of EPS and XPS boards and blocks, including custom CNC cutting to meet exact dimensions. Choosing between these foams starts with understanding their core differences:

EPS (Expanded Polystyrene)

EPS is made by expanding polystyrene beads using steam and pressure, forming a lightweight but rigid material that can be cut into various shapes and sizes. EPS is available in multiple density grades (e.g., H, VH), and is highly customisable for block-outs and void forms.

XPS (Extruded Polystyrene)

XPS is manufactured through an extrusion process, producing a closed-cell foam with superior moisture resistance and higher compressive strength at lower thicknesses. XPS is ideal for permanent installations where water exposure is likely.

Key Differences Between EPS and XPS:

- Structure:

- Moisture Resistance:

- Compressive Strength: Both can be made strong, but XPS generally outperforms EPS of similar thickness in load-bearing scenarios.

- Thermal Insulation: XPS offers better R-values per inch, ideal where thermal performance is a secondary goal.

-

Cost: EPS is generally more affordable and better suited for short-term or large-scale block-outs.

Whether you're forming lift pits, stair voids, or architectural profiles, choosing the right foam type ensures that the product performs under pressure literally. In upcoming sections, we’ll break down the unique qualities of each foam and help you decide which to use based on compressive strength, moisture stability, density, and cost.

What is EPS (Expanded Polystyrene)?

EPS is one of the most widely used foams in construction due to its light weight, affordability, and adaptability. It’s produced by expanding polystyrene beads into a mold, resulting in a rigid block that can be cut into virtually any shape.

EPS comes in several density grades, such as:

- H Grade (High): Suitable for standard construction block-outs and formwork.

- VH Grade (Very High): Ideal for heavy loads, crane support, or large infrastructure voids.

EPS foam is commonly used for:

- Void forming in concrete slabs and footings.

- Staircase and lift shaft block-outs.

- Pipe and duct pass-throughs.

- Structural insulation in panels (when combined with other materials).

Key Benefits:

- Cost-effective for large-scale jobs.

- Lightweight and easy to handle.

- CNC cuts to exact shapes and dimensions.

- Environmentally friendly, as it can be recycled.

At The Foam Company, we offer a full range of EPS densities, including custom VH100+ grades engineered for civil applications. It’s a go-to solution for projects needing high precision with tight budgets.

What is XPS (Extruded Polystyrene)?

XPS is a closed-cell foam manufactured through an extrusion process, creating a dense and moisture-resistant material. It’s especially useful in applications where water resistance and long-term durability are essential.

Unlike EPS, which has a visible bead structure, XPS appears as a uniform, smooth-surfaced board or block. This structure gives it distinct advantages in:

- Underground or damp conditions.

- Slab edge insulation and under-slab forming.

- Permanent block-outs where moisture retention must be avoided.

Key Features of XPS:

- Higher compressive strength per thickness.

- Excellent resistance to moisture and mildew.

- Superior thermal insulation (higher R-values).

- Durable enough to remain embedded in concrete.

XPS is slightly more expensive than EPS but offers better performance in permanent or moisture-prone environments. It’s commonly used in:

- Basement wall forming.

- Retaining wall backfills.

- SIP panels or sandwich panels.

Structural & Moisture Differences

The structural and moisture resistance differences between EPS and XPS play a vital role in determining which foam is best for a given formwork application.

EPS:

- Open-cell structure means it can absorb moisture over time.

- Less dense than XPS, but available in high-load VH grades.

- Suitable for dry environments or short-term installs.

XPS:

- Closed-cell construction makes it highly moisture-resistant

- Maintains compressive strength even in wet or humid conditions.

- Best used where foam will stay embedded in the structure.

Summary Comparison:

| Feature | EPS | XPS |

|---|---|---|

|

Water Resistance |

Moderate |

High |

|

Density Range |

Medium to High |

High |

|

Ideal Use |

Temporary forms |

Permanent insulation/block-outs |

|

Cost |

Lower |

Higher |

In formwork exposed to rain, groundwater, or outdoor conditions, XPS provides added protection against deterioration. For most dry indoor pours or when the foam is removed post-pour, EPS (especially VH-grade) will perform just as well at a fraction of the cost.

Compression Strength Comparison

Compressive strength is a critical factor when deciding what foam is best for concrete formwork. It determines whether the foam can withstand the pressure of wet concrete without deforming.

EPS Compressive Strength (Typical):

- H Grade EPS: ~100 kPa

- VH Grade EPS (VH100+): 150–250 kPa

- Custom-engineered VH grades can go even higher for crane support or infrastructure needs.

- Typically 250–500 kPa, depending on thickness and brand.

- Maintains strength in wet conditions better than EPS.

This makes XPS ideal for:

- Under-slab forming with heavy live loads.

- Permanent installations in retaining walls or bridge decks.

EPS is still highly effective in most standard residential or commercial pours, especially when the proper grade is chosen.

Tips for Choosing by Load:

- Light loads/short-term: EPS H grade.

- Medium loads/larger pours: VH EPS (VH100+).

- Heavy loads or wet environments: XPS or high-end VH EPS.

When in doubt, our technical team can assess your pour size and recommend the right grade for your project's compressive strength needs.

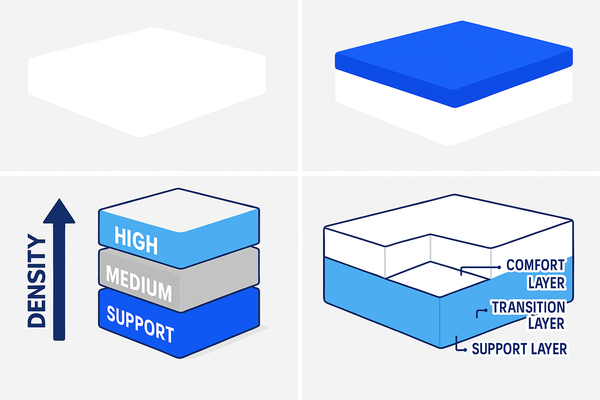

Foam Density and Its Impact on Performance

Foam density plays a critical role in how a product performs under pressure, particularly in concrete formwork and block-out applications. At The Foam Company, we help civil engineers, contractors, and builders choose the correct EPS or XPS foam density based on load requirements, moisture exposure, and installation preferences.

The denser the foam, the greater its compressive strength, durability, and resistance to deformation during concrete pours. However, increased density also affects cost, handling weight, and cutting characteristics, so it's important to match density with the project's specific needs.

Common Foam Density Ratings:

- EPS H Grade (High Density): Typically around 24–28 kg/m³.

- EPS VH Grade (Very High Density): Ranges from 30–38+ kg/m³ (e.g., VH100+).

- XPS Boards: Usually 30–40 kg/m³, with consistent performance across thicknesses.

When Does Density Matter?

- Load-bearing scenarios: Use VH-grade EPS or XPS where cranes, vehicles, or deep pours are involved.

- Precision work: High-density foams cut cleaner on CNC for detailed profiles and structural inserts.

- Moisture-prone areas: XPS or dense EPS reduces absorption and swelling risks.

- Permanent embeds: Denser foams ensure lasting shape and load tolerance.

Choosing the wrong density can result in foam collapse, shifting during pour, or long-term structural issues costing time, material, and safety.

At The Foam Company, our team provides expert recommendations on EPS H vs. VH grade, XPS board specs, and CNC design for any formwork task. If you're unsure, reach out with your load and shape requirements we'll match you with the optimal density foam for success.

Understanding Foam Density Ratings (e.g., VH Grade)

Foam density is measured in kilograms per cubic metre (kg/m³) and directly relates to the material’s compressive strength and structural performance. In the construction industry, common EPS density grades include:

- H Grade (High Density): Approx. 24–28 kg/m³

- VH Grade (Very High Density): 30–38+ kg/m³

- VH100+: Indicates foam capable of handling compressive loads over 100 kPa

These ratings are essential for civil engineers working on infrastructure, load-bearing formwork, and high-volume pours. The denser the foam, the more resilient it is under concrete pressure, crane loads, and structural embedment.

Foam density also affects:

- Cutting precision (denser foam holds fine CNC detail better)

- Handling weight (higher densities are heavier)

- Moisture resistance (denser foams absorb less)

At The Foam Company, we stock a wide range of EPS blocks, including VH100+ grade, designed for critical civil and commercial projects. Understanding and specifying density upfront helps avoid foam failure and ensures safety compliance.

H vs VH Grade EPS: Applications & Load Tolerances

Choosing between H and VH grade EPS depends on the formwork’s exposure to weight, duration of installation, and surrounding conditions. Here's how they compare:

- Great for general-purpose construction

- Suitable for small voids, light pours, or where foam will be removed post-pour

- Easier to cut and lighter to handle

- Common in residential and light commercial applications

- Engineered for heavier loads and structural support

- Withstands high compressive force without distortion

- Ideal for infrastructure like bridge decks, slab block-outs under crane loads, and footing reinforcement

- Used in civil projects and high-rise commercial builds

Load Tolerances (approximate):

- H Grade: ~100 kPa

- VH100+: 150–250+ kPa

When in doubt, we recommend choosing VH grade EPS for any formwork that will be supporting substantial weight or subject to long pour durations. The Foam Company can custom-cut both H and VH grade blocks based on your site’s specific tolerances and dimensions.

When to Use High-Density EPS (VH100+)

High-density EPS, particularly VH100+ grade, is designed for heavy-duty structural applications where typical H-grade foam may compress or deform under load.

Use VH100+ when:

- The concrete pour involves deep slabs or high pressure

- Foam supports are located under cranes or lifting equipment

- The formwork is left in place permanently

- You need repeat-use form inserts for precast or bulk production

- You require dimensional stability for long installations

Key Advantages:

- Higher compressive strength (~150–250+ kPa)

- Better performance under crane point loads

- Cleaner CNC finish for detailed profiles

- Safer for large-scale or long-duration pours

VH100+ foam is often the standard for civil and infrastructure projects such as bridge works, lift pits, tunnel formwork, and column bases. When formwork failure is not an option, VH100+ gives peace of mind.

At The Foam Company, we supply project-specific VH-grade EPS blocks, pre-cut to specification with fast lead times for projects across Australia.

How XPS Compares in Formwork Load Capacity

XPS foam is known for its exceptional compressive strength and uniform load distribution, making it an excellent alternative to EPS in certain scenarios.

Typical Load Ratings:

- XPS: 250–500 kPa compressive strength depending on board thickness and brand

- Performs well even in wet or underground conditions

- More stable under long-term load applications than EPS

Best Used When:

- Projects are exposed to moisture or chemical intrusion

- The foam is intended to be left in place permanently

- You require thinner material with higher load ratings

- Working with precast or sandwich panel applications

While XPS is generally more expensive than EPS, it offers superior moisture stability and compressive strength per millimetre. This makes it ideal for retaining wall block-outs, slab edges, and high-load internal voids.

The Foam Company stocks high-performance XPS boards, which can be CNC profiled or pre-cut to shape and delivered to your project site.

Foam Failure Risks from Improper Density Use

Specifying the wrong foam density in a concrete application can lead to project setbacks, safety concerns, and costly rework. Common risks of improper foam selection include:

- Compression or crushing under pour weight

- Movement or shifting of block-outs during pour

- Deformation resulting in incorrect void shapes

- Water absorption and swelling in damp environments

- Breakage when removing foam after curing

Why It Happens:

- Using H-grade EPS where VH or XPS is required

- Not accounting for long-term or live load pressure

- Exposure to ground moisture or curing chemicals not suited to low-density foams

How to Prevent It:

- Always calculate the expected load per square metre

- Choose foam based on duration and purpose (temporary vs permanent)

- Account for moisture exposure

- Consult with The Foam Company’s technical team before ordering

By choosing the right foam density, you ensure safe, smooth concrete pours and a professional finish every time. We’re here to help you make the best material decision for long-term performance.

Applications of Foam in Concrete Block-outs

Foam is widely used in concrete construction for creating voids, inserts, and forms that would be difficult or time-consuming to achieve with traditional materials like timber or metal. Thanks to its lightweight, easy-to-cut, and customizable nature, foam, especially EPS and XPS, has become the go-to solution for contractors, builders, and engineers across a wide range of construction sectors.

At The Foam Company, we manufacture and supply foam block-outs for:

- Residential slabs and footings

- Civil infrastructure projects

- High-rise and commercial formwork

- Bridges, tunnels, and transport structures

Whether the foam is temporarily used and removed post-pour or permanently embedded, the key is to match the right type and density of foam with the application's requirements. CNC custom cutting also allows for precise shapes, angles, and recesses, reducing time and improving the accuracy of the final structure.

Typical Applications:

- Electrical and plumbing voids in slabs

- Stair and lift shaft block-outs

- Beam pockets and footing recesses

- Bridge decks and expansion joints

- Concrete mold shaping for precast panels

Using foam in these scenarios saves time on-site, reduces material waste, and ensures consistent, repeatable results. Let’s break down some of these applications below.

Electrical and Plumbing Pass-throughs

Creating clean, consistent voids for electrical conduits, pipes, and service lines is one of the most common uses of foam in concrete slabs and walls. EPS and XPS blocks are ideal for this application because they:

- They are easy to shape for round or rectangular voids

- Stay in place during a pour if properly anchored

- Can be removed cleanly after curing

- Prevent concrete from clogging pass-throughs

At The Foam Company, we provide pre-cut foam cylinders, channels, and boxes to match electrical and plumbing specifications. Using foam reduces the risk of manual chiseling or drilling post-pour, which can damage the concrete or embedded services.

CNC-cut foam inserts also allow for complex conduit pathways, tiered voids, or integration with other structural features. Whether it’s a small residential slab or a multi-service commercial pour, foam ensures that the services can be routed with precision and minimal hassle.

Beam Pockets and Lift Shaft Voids

Beam pockets and lift shaft recesses require accurately placed voids to allow structural beams or mechanical systems to fit post-pour. Using foam makes forming these shapes much easier compared to timber framing or removable metal inserts.

Benefits of using foam in these areas:

- Can be custom-shaped to match lift or beam dimensions

- Reduces concrete overspill or form collapse

- Supports complex angles or stepped recesses

- Easy to remove or leave in-situ, depending on the project

Foam blocks are often used in shear walls, floor slabs, and elevator pits to create accurate beam seating zones or lift penetration points. With VH density EPS or XPS, you also get sufficient strength to resist the pour pressure and maintain dimensional stability until curing.

The Foam Company works with project engineers and site supervisors to produce CNC-cut inserts that ensure the beam or lift component fits perfectly post-pour, saving time and reducing remedial work.

Stairs and Footing Block-outs

Forming block-outs for stair returns, foundation steps, or footings can be tricky using traditional timber methods. Foam simplifies the process by allowing complex forms to be cut off-site and installed quickly.

Here’s how foam helps:

- Easily shaped into angled or tiered profiles

- Strong enough to support concrete weight during pour

- Reduces time spent framing or stripping timber forms

- Can be used in footings, step-down slabs, and suspended structures

VH-grade EPS or XPS foam is ideal for these block-outs because they offer dimensional stability, resist moisture, and don’t deform under the weight of large pours. Contractors appreciate the time savings on-site, especially when dealing with repetitive or mirrored stair structures.

At The Foam Company, we frequently manufacture pre-cut stair and footing forms based on engineer or architect drawings. These forms can also include built-in angles and rebates for steelwork or edge protection, streamlining your workflow from setup to pour.

Expansion Joints and Edge Protection

Foam is often used to create expansion joints in concrete slabs, roads, and bridge decks. These joints absorb movement caused by temperature changes, settling, or dynamic loads, helping to prevent cracking or structural failure.

Why foam works well here:

- Compressible and durable

- Custom-sized to joint widths and slab depths

- Resistant to moisture (especially with XPS)

- Can be left in place or removed depending on design

Edge protection using foam prevents concrete overspill during pour and creates clean slab edges or formed corners, particularly around stair voids, lift shafts, or penetrations.

The Foam Company supplies XPS boards and high-density EPS strip for expansion control, including bevelled and notched options. These can be embedded flush or recessed to allow for joint sealants or cover.

Using foam for expansion and edge control gives you consistent performance, a faster install process, and compliance with AS construction codes related to thermal and movement tolerances.

Bridge Decks & Infrastructure Projects

Large civil works, especially bridges, tunnels, and transport infrastructure, demand foam solutions that are strong, precise, and reliable. VH100+ EPS and XPS foam are commonly used in these applications due to their:

- High load-bearing capacity

- Dimensional accuracy for complex forms

- Resistance to moisture and environmental stress

- Lightweight properties, aiding crane handling

Applications include:

- Void fill under bridge decks

- Pier and abutment block-outs

- Cable trenches and utility pass-throughs

- Recessed anchor zones and embed shapes

These projects often require foam components that are pre-fabricated from CAD files, ensuring that every curve, recess, or embedded feature is exact. CNC cutting makes it possible to match the most challenging geometries, improving build efficiency and reducing on-site waste.

The Foam Company has supplied foam to major infrastructure projects across Australia, working alongside civil engineers and government contractors to deliver durable, high-performance solutions that stand up to both mechanical and environmental demands.

Benefits of Using Foam in Formwork

Using foam for concrete block-outs and formwork delivers a wide range of practical, economic, and structural advantages for civil, commercial, and residential projects. Compared to traditional materials like wood, steel, or metal inserts, foam stands out due to its customizability, lightweight nature, and durability under load.

At The Foam Company, we help engineers and contractors save both time and money on-site by supplying pre-cut EPS and XPS foam forms that align precisely with project specs. This eliminates guesswork, reduces labor, and improves final concrete finish quality.

Here are the major benefits of foam in formwork:

- Precision Customization: CNC cutting allows you to shape foam into any void or form, no matter how complex.

- Quick Installation: Foam blocks are light, easy to handle, and slot straight into place with minimal fixings.

- Time & Waste Reduction: Faster setup and minimal offcuts or rework save time and reduce on-site waste.

- Weather Resistance: XPS and VH-grade EPS resist moisture, UV, and site contaminants far better than timber.

- Cost-Effective for Scale: Ideal for repetitive use, especially for high-volume construction or modular builds.

Precision & Customization with CNC Cutting

One of the biggest advantages of foam formwork is the high level of precision it offers, thanks to CNC (Computer Numerical Control) cutting. Whether you need complex shapes, angles, or embedded features, CNC-cut foam ensures a perfect fit every time.

Why it matters:

- Eliminates manual cutting errors and inconsistencies

- Allows for intricate architectural designs and sloped surfaces

- Reproduces multiple identical forms quickly and accurately

- Seamlessly integrates with steel reinforcement and other embedments

At The Foam Company, we convert your CAD or hand-drawn plans into exact foam block-outs, reducing misalignment and ensuring your pour goes smoothly. This kind of precision is critical in applications like beam pockets, lift shafts, curved stairwells, and bridge elements.

We can also add bevels, grooves, chamfers, and step-ins to ensure the foam aligns precisely with your concrete design.

Reduced Waste and Time on Site

Time is money on any construction site, and foam helps you save both. Traditional forming materials require skilled labor, cutting, bracing, and dismantling. Foam, especially when pre-cut, arrives ready to install.

Advantages include:

- No on-site shaping or saw-cutting

- Reduced material offcuts and breakage

- Eliminates formwork dismantling delays

- Improves project turnaround time

By using pre-fabricated foam block-outs, your team spends less time preparing and more time pouring. This is especially helpful on large projects where repetition and accuracy are crucial, such as apartment slabs, tilt-up panels, and infrastructure decks.

At The Foam Company, we’ve seen clients reduce setup time by up to 50% compared to timber for void forming, especially on bulk or complex projects.

Lightweight and Easy Installation

One of foam’s most practical benefits is how light and easy to handle it is. Even large blocks of EPS or XPS can be carried by one or two workers without mechanical assistance, saving valuable time and effort.

Key benefits:

- Quick and safe manual handling

- Easy to install in overhead or hard-to-reach spots

- No need for cranes, forklifts, or rigging in most cases

- Reduces strain and improves worker safety

Lightweight foam is especially useful in high-rise construction, where transporting materials up scaffolding or floors can be challenging. Contractors can also make last-minute adjustments on-site with simple hand tools, adding flexibility during installation.

At The Foam Company, we supply foam block-outs with clear installation markings, helping your team position forms correctly without the risk of misalignment.

Resistance to Weather & Moisture Damage

Unlike timber, foam doesn’t swell, rot, or degrade when exposed to rain, humidity, or ground moisture. This is especially important in open slab pours, underground structures, or wet-weather sites.

Foam benefits in adverse conditions:

- EPS (VH grade) resists water absorption

- XPS is highly moisture-resistant and suitable for wet zones

- No warping, splintering, or cracking

- Stable in UV-exposed and buried applications

Foam’s resistance to moisture extends its lifespan, making it suitable for permanent embedded applications. Whether used in underground voids, retaining wall footings, or damp bridges, foam retains its shape and strength.

At The Foam Company, we guide our clients on selecting the right density and foam type (VH EPS vs XPS) depending on the site’s moisture exposure and environmental conditions.

Cost-Effectiveness for Bulk or Repetitive Use

For builders and engineers working on repetitive pours like multi-residential slabs, tilt-up panels, or infrastructure decks, foam provides a scalable and budget-friendly solution.

Cost-saving aspects of foam formwork:

- Lower material costs vs. timber or metal

- Minimal waste and zero rework

- Faster install equals lower labor costs

- Ideal for standardised, repeat block-outs

Because foam can be reused for repetitive non-load-bearing applications, it adds value over multiple pours. Even when used once, the reduction in labor, error correction, and waste disposal makes it more cost-effective in the long run.

At The Foam Company, we offer competitive pricing for bulk orders and repeat projects, with custom cutting discounts for volume-based production. Whether you need 100 identical void forms or 10 unique pieces, we ensure that the solution is both high-performance and cost-efficient.

CNC Custom Cut Foam Solutions

When it comes to concrete formwork and block-outs, precision is everything. That’s why at The Foam Company, we’ve invested in advanced CNC (Computer Numerical Control) foam cutting technology to deliver the most accurate and customizable foam solutions in Australia.

CNC cutting allows us to turn your engineering plans, CAD files, or sketches into perfectly shaped foam inserts and molds. Whether you need curved lift shaft forms, bevelled edge voids, or angular stair block-outs, CNC machinery ensures that every cut is clean, consistent, and repeatable.

This service is ideal for:

- Complex formwork requiring exact angles or radii

- High-volume, repetitive slab or panel pours

- Custom-shaped concrete features or penetrations

- Large infrastructure projects with detailed specifications

Our experienced in-house team handles everything from design review to execution, working closely with builders, civil engineers, and site managers to ensure on-time, on-spec delivery.

Why choose CNC-cut foam?

- Reduces on-site cutting and mistakes

- Speeds up installation time

- Ensures accurate fits for embedment and pass-throughs

- Allows integration with BIM and architectural models

- Minimizes waste through efficient nesting and shaping

How CNC Cutting Works at The Foam Company

Our CNC foam cutting process begins with your project data, which can be a CAD file, a PDF drawing, or even a hand sketch. From there, our design team transforms that input into a precise cut path using industry-grade software.

The steps include:

- Reviewing your drawings or CAD files

- Converting shapes into cut-ready formats

- Programming tool paths for high-speed CNC machines

- Cutting EPS or XPS blocks to match exact dimensions

CNC routers and hot-wire machines are capable of producing clean edges, complex profiles, and intricate void shapes in a fraction of the time it would take manually.

Whether you need symmetrical designs, stair treads, or compound angles, our CNC equipment ensures every cut is exact. This is particularly beneficial for projects requiring bulk block-outs with consistent tolerances across hundreds of units.

Design to Execution Workflow

At The Foam Company, we pride ourselves on having a streamlined process from design through to dispatch. We work closely with you at every step to make sure the final product is not just accurate but practical to install.

Our typical CNC workflow includes:

- Consultation on your formwork or void requirements

- Review of site plans, slab details, or concrete drawings

- Digital modeling and cut file generation

- Trial layout and client approval

- CNC cutting, packaging, and delivery to the site

We ensure that all foam forms are clearly labelled, organized by pour phase, and packaged securely for transport. This simplifies installation and helps your team stay on schedule.

For repeat projects, we store your designs and files for future cutting, ensuring you get the same quality result every time without needing to resubmit specs.

Material Sizing, Angles, and Embeds

CNC cutting allows for total control over dimensions, angles, and embedded features, giving you the flexibility to tackle complex shapes or design requirements that timber or steel just can’t match.

We can cut foam forms with:

- Compound angles and bevels

- Radiused edges or curved profiles

- Step-down and step-up configurations

- Grooves for reinforcement bars or pipe inserts

- Custom thicknesses and multilayer builds

Our machines handle both EPS and XPS foam blocks in various densities. If your project requires foam inserts that double as both void formers and insulation, we can match the right grade and thickness to suit.

No matter how intricate your detail, our CNC process ensures that the final foam component arrives ready to install, with minimal to no on-site trimming required.

Accuracy & Repeatability for Complex Structures

For large-scale or repetitive construction work, consistency is crucial. Foam forms that vary by even a few millimetres can cause misalignment, void-filling issues, or rework after the pour. That’s why CNC cutting is the go-to solution for accurate, repeatable production.

Why it works:

- Every cut is made from the same digital file

- Dimensional errors are eliminated

- Repetition across multiple units is exact

- Forms fit precisely within the reinforcement cage or slab grid

This is especially important for:

- Precast panels

- Tilt-up construction

- Lift cores and stairwell returns

- Beam and footing pockets

At The Foam Company, we maintain tight quality control standards to ensure that what you order is exactly what’s delivered every time. With our CNC process, complex doesn’t mean complicated. It just means efficient.

Uploading CAD/Architectural Drawings for Foam Orders

To make things as simple as possible for our clients, we offer a digital upload service for architectural or engineering drawings. If you’ve got a CAD file, PDF, or even a hand-drawn sketch, we can turn that into a ready-to-cut foam design.

Accepted file types:

- .DWG, .DXF, .PDF, .AI (Illustrator), or.SKP (SketchUp)

- Hand sketches with scale and measurements

- 3D models for architectural features

Simply upload your drawings via our website or email them directly to our technical team. We’ll review the files, clarify any design questions, and send you a quote and timeline for production.

This system saves you time and allows us to collaborate early in the project cycle, helping avoid issues during pour prep. For returning clients, we keep your previous designs on file so that future orders are as easy as a few clicks.

Choosing Between EPS and XPS for Your Project

When selecting foam for concrete formwork, void filling, or block-outs, the decision between EPS (Expanded Polystyrene) and XPS (Extruded Polystyrene) can significantly impact performance, durability, and cost. Each foam type has unique properties that make it suitable for different construction applications.

At The Foam Company, we help clients make this decision based on project-specific conditions like load requirements, exposure, curing environment, and insulation needs. We stock both EPS in various densities (including H and VH grades) and XPS boards to accommodate everything from small residential jobs to heavy-duty infrastructure projects.

Here’s how we guide clients through the decision-making process:

- Load-bearing requirements: VH-grade EPS is ideal for crane pads, lift shaft cores, and footings.

- Moisture exposure: XPS performs better in wet or underground environments.

- Formwork reusability: EPS can be recycled or reused when handled correctly.

- Insulation integration: XPS provides a better R-value if thermal performance is also needed.

- Budget and lead times: EPS is more economical and readily available for bulk projects.

Site Conditions & Load Requirements

The first and most critical factor is understanding site-specific load and stress conditions. If the foam needs to resist concrete pressure, crane load, or curing expansion, you’ll need a high-density solution like VH-grade EPS (e.g., VH100 or higher) or XPS.

EPS is ideal when:

- Used as a compressible fill in footings or voids

- Load is temporary (e.g., during pour only)

- The foam is shaped into deep block-outs or inserts

XPS is preferred when:

- Ground pressure is high and continuous

- Foam will stay embedded permanently

- The pour involves post-tensioned slabs or retaining walls

At The Foam Company, we match your formwork application with the right density EPS or XPS to ensure stability, safety, and long-term performance.

Exposure to Moisture or Chemicals

Environmental exposure plays a major role in foam selection. On sites where foam is exposed to wet conditions, chemicals, or underground moisture, XPS is the superior choice. Its closed-cell structure makes it highly resistant to water absorption and breakdown.

Consider XPS if your site involves:

- Below-grade formwork (e.g., retaining walls, footings)

- Harsh weather, frequent rain, or water runoff

- Industrial exposure to curing agents or solvents

EPS can still be used in outdoor or damp settings, but VH-density grades should be selected for improved durability. Coatings or membranes can also be applied to EPS to enhance protection if cost is a factor.

At The Foam Company, we can recommend coatings or suggest XPS alternatives depending on your environmental risks and lifespan expectations.

Temporary vs Permanent Void Fill

Another consideration is whether the foam form is meant to be removed after the pour or left embedded in the structure. For temporary block-outs, EPS is generally more cost-effective and easier to extract. It can be cut, broken down, or dislodged cleanly after the concrete sets.

Use EPS when:

- The form will be stripped after the pour

- Access allows for manual removal or suction

- You’re forming sleeves, stair returns, or beam notches

Use XPS when:

- Foam is staying inside the concrete

- Insulation is a bonus requirement

- High-strength, waterproof properties are needed post-pour

At The Foam Company, we help you determine whether you need a sacrificial insert or a long-term embedded form, and guide you on density and finishing options for both EPS and XPS.

Insulation Needs (If Required)

In some projects, foam serves a dual purpose: formwork and thermal insulation. In these cases, XPS provides superior thermal performance due to its higher R-value and resistance to moisture intrusion, making it ideal for insulated slabs, basements, or rooftop formwork.

XPS offers:

- R-values typically range from R1.3 to R5+

- Low water absorption (less than 0.5%)

- Long-term thermal efficiency

EPS can also offer insulation benefits, especially in VH grades, but its thermal properties are slightly lower, and it may absorb moisture over time unless treated or coated.

If your project has energy efficiency goals or you’re working in thermally sensitive environments, XPS can add both formwork function and insulation value in one step.

Budget and Lead Times Consideration

Project budgets and schedules are always a factor. EPS is often the most budget-friendly option, especially for large volumes or temporary applications. It’s widely available, easier to source in custom sizes, and quicker to CNC cut for immediate dispatch.

Choose EPS if:

- You’re working on a tight budget

- Custom shapes and bulk quantities are needed

- Lead time is short and delivery is urgent

Consider XPS if:

- Moisture resistance or permanent embedment is a priority

- You're using it for dual insulation and forming roles

- Budget allows for a slightly higher upfront cost for longer-term gains

At The Foam Company, we maintain stock of both EPS and XPS and can advise on lead times based on your project timeline. We also offer volume pricing, which makes high-density EPS a smart choice for high-volume builders or repeat-use applications.

Installation Guidelines and Safety

Proper installation of foam in concrete block-outs and formwork ensures the best performance, structural integrity, and safety on-site. At The Foam Company, we work closely with site teams to support correct placement, anchoring, removal, and disposal practices because even the best foam can underperform if not handled the right way.

Installing EPS or XPS foam isn’t difficult, but it does require attention to detail, especially in high-pressure or complex slab configurations. From anchoring to pre-cutting and compatibility with concrete additives, following best practices reduces risks and ensures everything works seamlessly during the pour.

Our foam products are delivered clearly labelled and job-ready, but here are the key things to remember during installation:

- Use appropriate fixing methods to prevent floatation or shifting

- Seal foam where needed to prevent concrete bleed or water ingress

- Cut on-site only when necessary using proper tools (hot wire or fine-tooth saws)

- Protect foam from damage during rebar placement or walking over forms

- Follow safety guidelines for cutting or removing embedded materials

Anchoring or Holding Foam in Place

A major consideration when placing foam into a concrete form is making sure it stays fixed in position during the pour. Foam is lightweight by design, great for handling, but it can float, shift, or rotate if not properly secured.

Best anchoring practices include:

- Spot-gluing EPS to the formwork using foam-safe adhesive

- Using timber or steel supports on the sides

- Embedding foam between bar chairs or mesh

- Screwing through the base of XPS boards (if staying in-slab)

For vertical voids like lift shafts or beam pockets, mechanical bracing may be required to prevent collapse or movement under concrete pressure. We can advise on anchoring techniques tailored to your foam's size, density, and placement orientation.

Compatibility with Concrete Additives & Curing

Some concrete mixes use additives like plasticisers, accelerants, or chemical retarders to improve performance. While EPS and XPS foam are chemically inert in most cases, it’s still important to check compatibility, especially for permanently embedded forms.

Key considerations:

- EPS may degrade if exposed to solvents or hydrocarbon-based additives

- XPS has higher resistance to chemical reactions and is safer in aggressive curing environments

- Use protective coatings on foam when curing at elevated temperatures or in hot weather

- Avoid direct spraying of reactive chemicals onto bare foam surfaces

When in doubt, contact us with your concrete mix specification. We’ll advise whether coatings or alternative materials are needed. Ensuring foam doesn’t degrade or react during curing is critical for structural consistency and foam integrity.

Removing Foam Post-Pour

In many cases, foam forms are designed to be removed after the concrete has set. This is especially true for block-outs, pass-throughs, and temporary inserts. The removal process must be done carefully to avoid damaging the surrounding concrete or causing blowout fractures.

Recommended removal tips:

- Wait until concrete has reached sufficient curing strength

- Use a blunt-edge tool or hook to pull out the foam manually

- For EPS, score with a utility knife and break apart

- For deeper block-outs, use a reciprocating saw (not hammer force)

- Always clean out foam residue before installing hardware or fittings

VH-grade EPS may be tougher to remove due to its high density. In these cases, pre-cutting the foam with removal grooves before pouring can make the job easier later. We can CNC your forms with notches or pull handles built in, making removal faster and more efficient.

On-Site Cutting vs Pre-Cut Blocks

While on-site cutting may seem convenient, pre-cut foam blocks save significant time and reduce mess. With CNC cutting, your void forms arrive accurately shaped and sized, ready to place without trimming.

Why avoid on-site cutting:

- Creates dust, mess, and uneven edges

- Slows down crew productivity

- Increases the risk of wrong dimensions or poor fits

- Waste materials may clog drains or blow across the site

However, for minor adjustments or field modifications, use:

- Hot-wire cutters for clean edges

- Fine-tooth saws or blades for EPS

- Scoring knives for trimming XPS panels

We always recommend ordering your block-outs and inserts pre-cut to design. If you need flexibility, we can also ship blank foam sheets or oversized blocks with cutting guides provided.

Disposal or Reuse Considerations

Sustainability is an increasingly important consideration on construction sites. Foam waste, when managed correctly, can be reused or recycled rather than sent to landfill.

EPS disposal and reuse tips:

- VH-grade EPS can be broken down and reused in backfill or as light form filler

- Clean EPS is recyclable and accepted by select recycling centers

- Avoid mixing with contaminants (adhesives, concrete bits) to keep it reusable

XPS waste should be:

- Collected and stored separately

- Cut into manageable pieces for recycling

- Avoid mixing with wet cement or chemical coatings

At The Foam Company, we promote responsible disposal and can guide your team on reuse, on-site crushing, or off-site recycling options depending on local council regulations. We can also supply foam in sizes that minimize offcut waste from the start.

Where to Source High-Performance Construction Foam in Australia

Finding reliable, engineered foam products for concrete block-outs and formwork shouldn’t be complicated. At The Foam Company, we’ve made it our mission to support builders, civil engineers, and contractors with high-quality EPS and XPS solutions that meet Australian construction standards.

With decades of experience and a dedicated production facility, we supply foam for projects ranging from residential slab voids to major infrastructure works. Whether you're looking for H- or VH-grade EPS, moisture-resistant XPS boards, or CNC custom-cut inserts, we’re ready to assist from design to delivery.

Here’s what sets us apart as your go-to source for construction foam:

- EPS Foam Blocks in multiple densities (H100–VH200)

- XPS Boards for high moisture resistance and insulation value

- Custom CNC Cutting for stair voids, beam pockets, and lift shafts

- Bulk Supply Pricing for civil, commercial, and repeat orders

- Fast Turnarounds with local delivery across Australia

We don’t just sell foam, we solve problems. Our team offers technical guidance, site-specific recommendations, and custom quoting to ensure your foam performs perfectly, every time.

The Foam Company’s EPS & XPS Range

We manufacture and stock a wide variety of EPS and XPS foam products designed for the rigours of the Australian construction environment. Our foam is engineered for strength, durability, and moisture control, ensuring long-lasting performance in slabs, voids, and wall cavities.

EPS options include:

- H100, H150 for light- to medium-duty voids

- VH100, VH150, VH200 for crane pads, structural block-outs, and bridge decks

XPS products include:

- Closed-cell XPS boards in standard thicknesses

- Ideal for below-grade formwork and permanent thermal insulation

- Available in full sheets or cut-to-size

All foam products are manufactured to industry tolerances and are suitable for commercial, civil, and infrastructure projects. Need something specific? Just ask, we can cut foam to spec or recommend the best solution based on your load, exposure, and installation requirements.

Technical Support & Specifications

One of the key differences with The Foam Company is our technical know-how. Whether you're an estimator, engineer, or project manager, we provide clear specifications, datasheets, and recommendations tailored to your job.

Our technical support includes:

- Foam density selection based on load and void depth

- CNC cut file checks for CAD and architectural drawings

- Compatibility guidance for rebar, fixings, or curing agents

- Advice on foam coatings or chemical resistance (if needed)

We also provide documentation that complies with Australian Standards, including compressive strength ratings, moisture absorption rates, and fire retardancy info, where applicable.

Bulk Supply for Builders & Engineers

Whether you need 20 inserts for a residential slab or 200 blocks for a civil job, we can scale up to meet your volume demands. We work closely with engineers, specifiers, and procurement teams to supply foam at bulk rates and meet construction timelines.

What we offer:

- Consistent stock levels for VH-grade EPS and XPS

- Long-length EPS blocks (up to 5m) for large void fills

- Palletised deliveries for cranes or forklifts

- Repeat job support for builders with recurring designs

- On-time delivery to metro and regional sites

If your project requires repeat components or staged delivery, we’ll help you plan your order to reduce waste, store efficiently on-site, and stay within budget.

Lead Time & Delivery Availability

We know that construction schedules can change quickly. That’s why we maintain a responsive lead time on all EPS and XPS orders. Standard shapes can often be dispatched within 2–4 business days, and CNC-cut inserts are typically turned around in 5–7 business days, depending on volume.

Delivery capabilities include:

- Metro delivery to Sydney, Melbourne, Brisbane, Perth & Adelaide

- Regional site delivery with tail-lift or crane-off options

- Direct-to-site bulk delivery for infrastructure projects

- Pick-up available from our main warehouse in Victoria

Our logistics team will work with your project manager or builder to coordinate smooth, reliable delivery even to remote or hard-to-access locations.

Request a Custom Quote

If you're ready to specify foam for your project or just need pricing for budgeting, our team is here to help. Simply send us your drawings, dimensions, or quantities, and we’ll provide a custom quote based on your exact needs.

To get started:

- Upload CAD or architectural files directly via our website

- Send PDF plans or void dimensions to our support email

- Let us know the foam type, density, and quantity required

- Ask us for density guidance if you’re unsure. We’re happy to advise

You’ll receive a clear, itemised quote within 24–48 hours, with lead time and freight options included. Our team can also supply samples or technical sheets upon request.

We take pride in being a trusted foam supplier for civil, residential, and commercial clients across Australia. With The Foam Company, you don’t just get foam, you get expertise, precision, and support every step of the way.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.