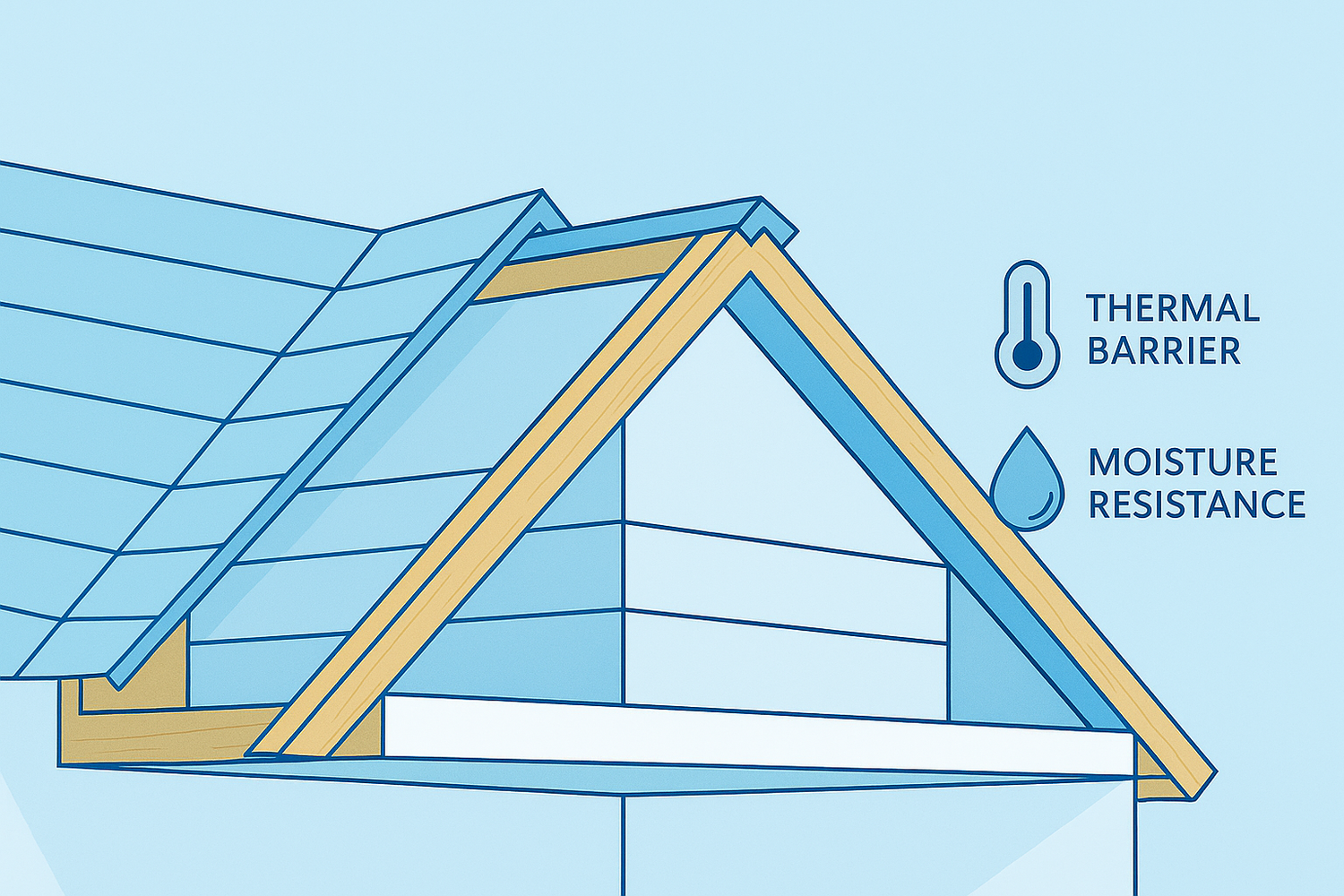

In the modern construction landscape, energy-efficient roofing insulation is crucial for sustainable living and reduced energy bills. One material leading this transformation is Extruded Polystyrene (XPS). Known for its rigid structure and superior moisture resistance, XPS is increasingly popular as both a roof insulation board and one of the top ceiling insulation materials.

This detailed guide explores how XPS outperforms traditional options like EPS or fiberglass. We’ll look at the material's benefits, installation methods, real-world applications, and why it's the best insulation for roofs and ceilings in both residential and commercial buildings.

Understanding Extruded Polystyrene (XPS) and Its Properties

Extruded Polystyrene (XPS) is a rigid foam board insulation material known for its excellent thermal performance, durability, and moisture resistance. It is produced using an extrusion process, which creates a closed-cell structure, a design that significantly enhances its strength and insulating capabilities.

What Makes XPS Insulation Unique?

Thanks to its manufacturing process, XPS insulation stands out due to several key properties:

- High Density and Structural Integrity: XPS boards are denser and more rigid compared to other foam insulation types like Expanded Polystyrene (EPS). This density provides excellent compressive strength, making XPS capable of withstanding heavy loads and mechanical stress. It can be used in environments where foot traffic or pressure from building materials is expected.

- Consistent Thermal Resistance Across the Board: One of the major advantages of XPS insulation is its uniform R-value throughout the panel. This means no weak spots or thermal bridges, ensuring continuous and effective insulation performance across the entire surface.

- Superior Water Repellency: The closed-cell structure of XPS acts as a barrier against moisture. Unlike many other insulation types, XPS doesn’t absorb water, which helps maintain its insulating properties even in damp or high-humidity conditions. This makes it especially suitable for use in basements, roofs, and outdoor structures.

Key Technical Benefits of XPS Insulation

Here are some standout technical advantages that make XPS a top-tier insulation material:

- R-Value Performance: XPS insulation typically offers an R-value ranging from R-5 to R-6 per inch, depending on the product and manufacturer. This high R-value means it provides excellent resistance to heat flow, helping to improve energy efficiency and reduce heating and cooling costs.

- High-Density Foam: Its robust construction resists compression and mechanical wear, making XPS ideal for structural applications or areas under load, such as under concrete slabs, rooftop decks, or flooring systems.

- Waterproof and Moisture Resistant: Unlike fiberglass or EPS, XPS boards repel water and retain their insulation properties even after prolonged exposure to damp environments. This is critical in applications like roof insulation, where moisture intrusion can be a problem.

- Fire Resistance: Many modern XPS products are enhanced with fire-retardant additives, helping to reduce the risk of flame spread. However, it’s essential to check the product specifications and local building codes for compliance and safety.

- Long-Term Durability: Over time, some insulation materials may degrade or lose their effectiveness, especially when exposed to fluctuating temperatures and moisture. XPS, however, maintains its dimensional stability and insulating performance, even in extreme cold or wet conditions, making it an ideal XPS insulation for cold climates.

Common Applications of XPS Insulation

Because of its strength, thermal efficiency, and water resistance, XPS insulation is widely used in both residential and commercial construction projects. Some popular uses include:

- Flat or Sloped Roofs: XPS boards are often installed under roofing membranes or above roof decks to provide continuous insulation and protect the structure from temperature extremes.

- Suspended Ceilings: For interior insulation, especially in basements or commercial buildings, XPS is used above suspended ceilings to reduce heat loss and improve comfort.

- Basement Ceilings and Walls: XPS is a popular choice for insulating basements, where moisture resistance is crucial to prevent mold growth and structural damage.

- Sheds and Detached Structures: For garages, workshops, and outdoor buildings, XPS offers reliable thermal performance while resisting the elements.

- Under Concrete Slabs: Thanks to its compressive strength, XPS can be laid beneath concrete slabs in both residential and industrial buildings to improve energy efficiency from the ground up.

Still on the fence about XPS insulation? Give us a call or drop us a message. Our down-to-earth foam pros will listen to what you’re planning and walk you through the options, no hard sell, just straight up help.

Key Benefits of XPS Insulation for Roofs and Ceilings

XPS offers a host of performance-related and environmental benefits. Here’s why it’s preferred by builders and architects:

-

Superior Thermal Performance

- A high R-value means better energy retention.

- Maintains consistent indoor temperatures.

- Reduces the workload on HVAC systems.

- A critical component for green building projects.

-

Moisture Resistance

- Closed-cell structure prevents water absorption.

- Reduces the risk of mold and mildew.

- Suitable for XPS insulation for basements and damp ceiling areas.

-

Durability and Longevity

- Resists compression and maintains shape.

- Reliable XPS insulation performance over time.

- Minimal deterioration in thermal efficiency.

-

Lightweight and Easy to Handle

- Ideal for DIY insulation projects.

- Quick to cut and install.

- Reduces labor and time costs.

-

Acoustic Benefits

- Effective soundproof ceiling insulation.

- Reduces outdoor noise, improving comfort.

-

Environmental Efficiency

- Lower carbon footprint due to energy savings.

- Recyclable material with growing use in sustainable insulation materials.

XPS Insulation Installation Guide

Installing Extruded Polystyrene (XPS) insulation correctly is essential to ensure it performs to its highest potential. By following these detailed steps, you can achieve an efficient, long-lasting insulation system.

- Site Evaluation

Before starting, assess the existing insulation and check the area for any moisture issues. It’s crucial to inspect the load-bearing capacity of the surfaces where the XPS will be installed. You should also determine the required thickness of the XPS insulation based on your desired R-value . Higher R-values will require thicker boards, so ensure you’ve calculated this correctly for optimal energy efficiency.

- Surface Preparation

The surface must be clean, dry, and free of dust, oil, or moisture. Any debris or contaminants could interfere with the adhesion of the XPS insulation, reducing its performance. Additionally, ensure that the surface is level and smooth to provide a strong foundation for the insulation.

- Cutting XPS Boards

XPS insulation boards are easy to cut, but precision is key for a proper fit. Use a hot wire cutter or a utility knife to make clean, accurate cuts. For corners or fixtures, measure and cut the boards carefully to fit the shape of the area.

Guides on cutting XPS insulation are easy to find, but the fastest way to get a clean, accurate cut is to contact our team so we can walk you through it step by step.

- Fixing the Insulation

You can attach XPS boards by either mechanically fastening them with screws or nails, or using an adhesive suitable for foam. Apply the boards in staggered layers to minimize thermal bridging, which helps maintain the insulation’s efficiency.

- Sealing and Inspection

Once the XPS is installed, ensure all joints are sealed with specialized tape or foam sealant. Inspect the installation thoroughly for any air gaps, misalignment, or compression. The insulation must be in full contact with the surface to ensure there are no thermal bridges or leaks.

For larger commercial projects or complex installations, contact our consultant who specializes in XPS insulation to ensure optimal performance and longevity.

Environmental and Economic Impact of XPS Insulation

Opting for XPS isn’t just a functional choice it’s a smart environmental and financial decision.

-

Environmental Benefits

- Contributes to green building projects.

- Reduces GHG emissions by lowering heating and cooling needs.

- Manufactured using increasingly sustainable insulation materials.

-

Economic Benefits

- Higher initial cost offset by long-term energy savings.

- Reduced HVAC maintenance.

- Excellent ROI due to longevity and low upkeep.

-

Fire Safety

- Fire-resistant roof insulation options are available.

- Essential in high-risk fire zones and urban constructions.

XPS vs EPS Insulation and Other Alternatives

Choosing the right material means comparing performance, cost, and durability. Here’s how XPS stacks up:

-

XPS vs EPS Insulation

- XPS: Higher R-value, moisture-resistant, durable.

- EPS: Cheaper but prone to water damage and compression.

-

Foam Board Insulation Alternatives

- Polyisocyanurate: Great thermal value but costlier.

- Mineral wool: Fire resistant, but heavier and harder to install.

-

Polystyrene Insulation vs Fiberglass

- Fiberglass: Can sag and absorb moisture.

- XPS: Retains form and insulates more consistently.

Conclusion: Invest in Future-Ready Insulation

Extruded Polystyrene is more than just a foam board it's a commitment to comfort, efficiency, and sustainability. With superior R-value, moisture resistance, and a long life span, XPS remains the preferred choice for both residential and commercial insulation projects.

From the best XPS foam price comparison to expert advice on installations, The Foam Company supports your journey to a well-insulated, energy-efficient building.

Explore our range of XPS insulation today to future-proof your project with confidence!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.