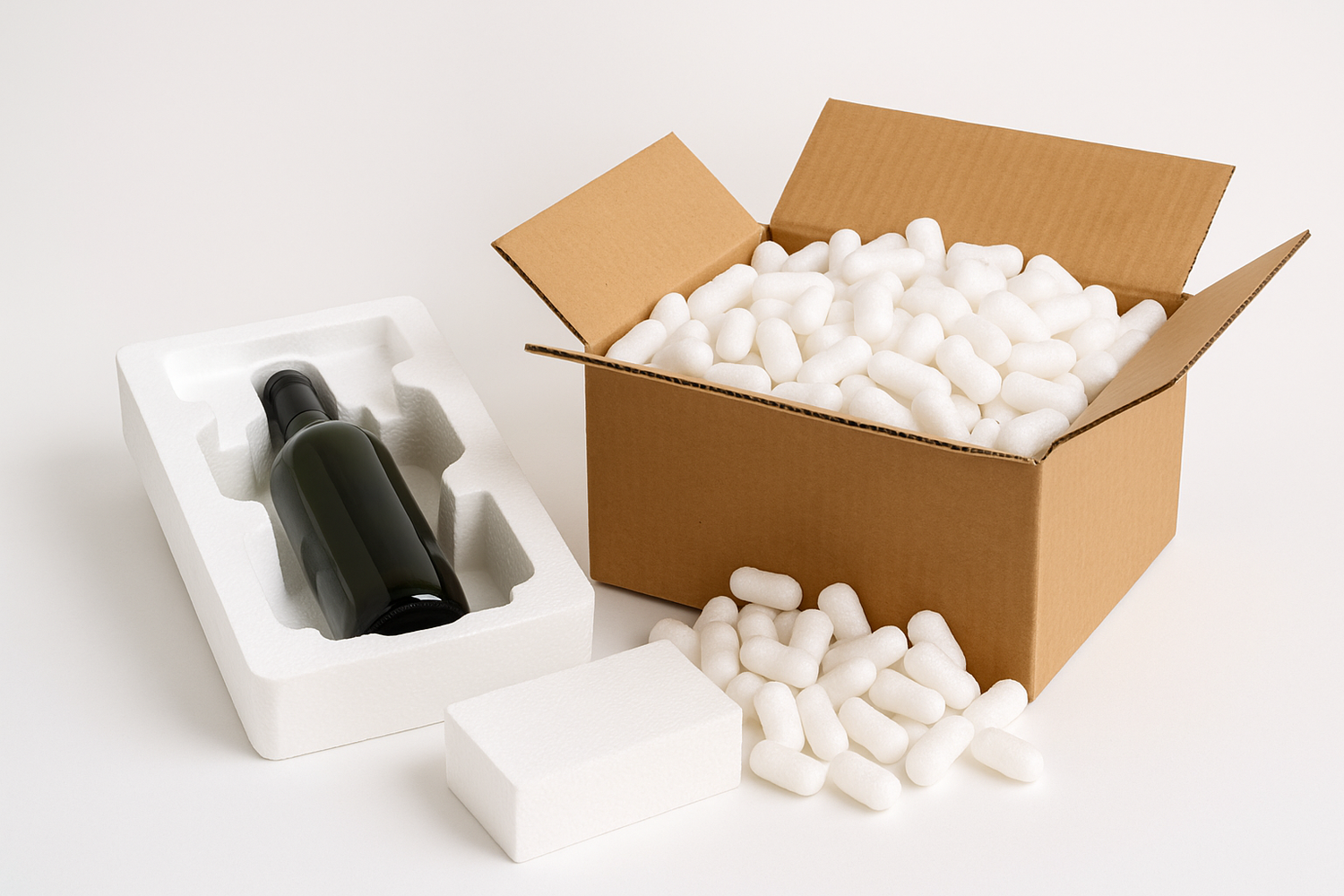

In today’s fast-paced, globalized market, packaging has become much more than simply a protective shell. It stands as a dynamic tool for product safety, transportation efficiency, brand storytelling, and sustainability initiatives. One material that truly embodies this evolution is Expanded Polystyrene (EPS). At its core, EPS packaging represents innovation—a lightweight, durable, and cost-effective solution that meets diverse packaging challenges.

Expanded Polystyrene is created by heating polystyrene beads with steam so that they expand and fuse together. This process produces a closed-cell structure that is up to 98% air. The result? A material that delivers exceptional insulation and cushioning without adding significant weight. EPS is available in many formats, including expanded polystyrene boxes and sheets tailored for specific packaging applications.

Key features include:

- Superior Shock Absorption: Protects fragile items from impact during transit.

- Customizable Design: Adaptable for irregular items with our custom-cut EPS foam options.

- Lightweight Cost-Effective: Minimizes shipping costs while improving handling.

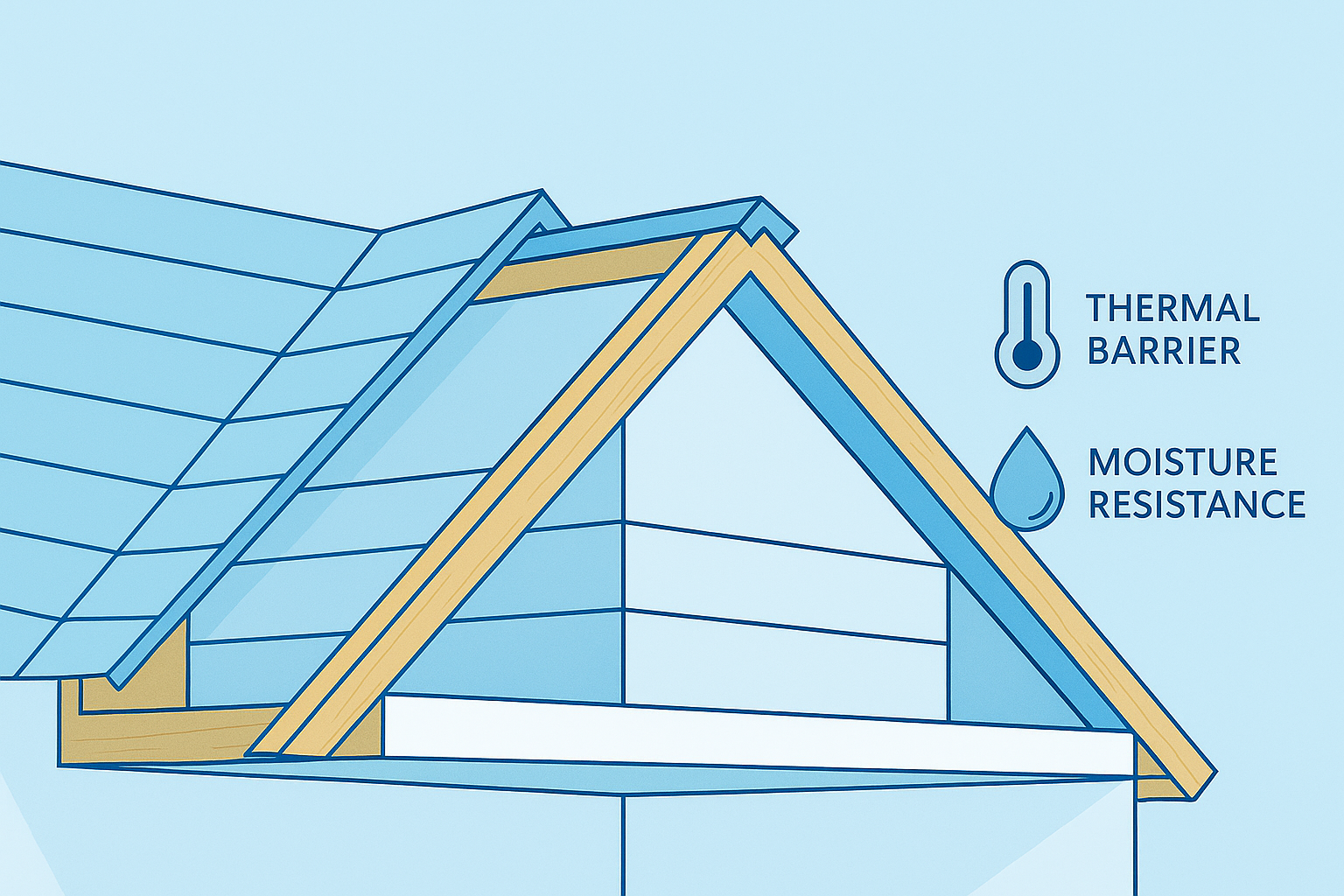

EPS’s thermal insulation ensures that food and pharmaceutical goods remain at optimal temperatures, making it indispensable for lightweight packaging solutions. Its moisture resistance further adds to its appeal for both indoor and outdoor shipments, boosting its role as protective foam packaging that stands up to diverse challenges.

Furthermore, the material’s adaptability allows for a host of applications. Whether protecting high-end electronics, serving as EPS for fragile items, or maintaining stringent temperature control, EPS remains at the forefront of modern packaging innovation. Its design flexibility also ensures that wasted material is minimized, contributing to broader sustainability goals.

In summary, by integrating EPS into your packaging strategy, you tap into a solution renowned for durability, efficiency, and eco-friendliness. Whether accessed through our extensive range of EPS packaging options or via tailor-made custom foam packaging, the benefits are clear—a smarter, more sustainable, and secure shipping experience.

Applications and Industry Benefits of EPS Packaging

Modern industries are continuously evolving, prompting a demand for packaging solutions that blend durability with efficiency. Expanded Polystyrene (EPS) has emerged as a key material in this transformation. When choosing EPS packaging, businesses gain access to a solution that offers outstanding protection across various sectors.

Key Industry Applications:

-

Electronics

- EPS for fragile items is crucial for safeguarding delicate circuit boards and components.

- Static and shock absorption capabilities of EPS ensure that expensive devices arrive without damage.

-

Food & Beverage

- Food-grade EPS packaging provides exceptional thermal insulation to maintain the correct temperature for perishable items.

- Its lightweight nature contributes to reduced shipping costs, making it an ideal choice for refrigerated transport.

-

Pharmaceuticals & Medical Supplies

- The moisture-resistant properties of EPS keep vaccines and medicines secure during transit.

- Its effectiveness in Thermal insulation packaging helps maintain efficacy and safety.

Advantages of EPS in Packaging:

- Lightweight Cost-Effective: Reduces energy costs during transportation and minimizes overall logistical expenses.

- Customizable Options: Available in various thicknesses, densities, and dimensions, allowing companies to tailor their solutions.

- Environmental Benefits: EPS is 100% recyclable, turning potential waste into raw materials for new products.

EPS’s adaptability facilitates its use in sectors requiring precise fitments and secure shipping. Additionally, the material’s shock-absorbing features are enhanced when designed with protective foam packaging techniques. This makes EPS indispensable for businesses focused on reducing product damage while adhering to strict quality standards.

In today’s competitive market, integrating EPS packaging into your operations isn’t just about protection—it’s about enhancing overall efficiency, minimizing costs, and adopting sustainable practices. For companies across electronics, food, pharmaceuticals, and industrial sectors, EPS provides the versatility and reliability needed to stay ahead.

Sustainability, Innovations, and The Foam Company Advantage

Sustainability is a growing priority in modern packaging, and Expanded Polystyrene (EPS) is evolving to meet these environmental challenges head-on. At The Foam Company, we’re dedicated to offering sustainable EPS packaging that serves your business while protecting our planet.

EPS’s lightweight construction results in reduced transportation emissions, cutting down on overall carbon footprints. Despite being petroleum-based, EPS is 100% recyclable, making it an integral part of modern recycling initiatives that transform used material into new products.

Sustainability and Eco-Friendly Practices:

-

Recyclability

- EPS is fully recyclable through specialized programs available across Australia.

- This transforms waste into raw materials for construction, design, and other sectors.

-

Energy Efficiency

- Its low density means less energy is required for transport and logistics.

- Cost-effective packaging materials help reduce overall production and shipping expenses.

-

Innovative Customization

- The adaptability of custom foam packaging ensures minimal wastage and supports environmentally friendly design.

- Different thicknesses and densities meet the precise needs of various industries, from high-tech electronics to temperature-sensitive pharmaceuticals.

Innovations in EPS technology are focused on improving fire safety, moisture resistance, and overall durability while adhering to EPS packaging regulations. Our products reflect the latest in packaging technology, delivering both robust performance and eco-friendly design.

At The Foam Company, we also ensure that every client benefits from our hands-on expertise in EPS packaging. Our local manufacturing guarantees high-quality, Australian-made products, while our commitment to environmental sustainability informs every step of our production. This dual focus on performance and ecological responsibility is what sets us apart as leaders in protective foam packaging.

By choosing our solutions, you are not only securing the safety of your products but also making a responsible choice for the environment. We take pride in offering tailored, innovative solutions that ensure your packaging needs are met without compromising sustainability.

Custom EPS Packaging Solutions Tailored for Your Business

Every business has its unique packaging requirements, and at The Foam Company, our custom EPS packaging solutions are built to adapt. Our ability to provide custom foam packaging designed precisely for your needs makes us a trusted partner across multiple industries.

Customization at Its Best:

-

Tailor-Made Dimensions

- We produce expanded polystyrene boxes and inserts that fit each product perfectly.

- Our technology allows for precision cutting and shaping, ensuring a secure fit every time.

-

Industry-Specific Adaptations

- Whether it’s EPS packaging for electronics that requires extra cushioning or food-grade designs for sensitive perishables, our solutions are engineered with care.

- Our custom-cut EPS foam is available in a range of thicknesses and densities tailored to match your product’s specifications.

-

Efficiency and Cost Savings

- Customized solutions reduce product movement and potential damage, saving on returns and wastage.

- The design flexibility allows efficient material use, contributing to lower production costs and optimized logistics.

The Foam Company Approach:

-

Collaborative Design Process

- We work closely with you to understand your unique product requirements and logistical challenges.

- Our team of experts provides guidance on the most effective protective foam packaging designs.

-

Quality Assurance

- Every custom EPS solution undergoes rigorous testing to ensure superior shock absorption and thermal insulation.

- Trust in our commitment to quality means that, whether using EPS packaging for fragile electronics or heavy industrial parts, the outcome is consistent excellence.

-

Flexibility & Scalability

- Our solutions are adaptable for both small-scale orders and large industrial needs.

- From lightweight packaging solutions to robust industrial applications, we provide a seamless integration into your supply chain.

Emphasizing a personalized approach, we ensure that every detail is covered—whether it’s the cushioning required for EPS for fragile items or the design modifications needed for specialized shipments. Our dedication to delivering precision-engineered custom-cut EPS foam reinforces our promise to support your business goals, reduce shipping costs, and improve overall protection.

By selecting a tailored EPS solution from The Foam Company, you invest in a packaging strategy that perfectly aligns with your product’s needs and offers a competitive edge in the market. Contact our foam experts today to find the perfect fit for your products.

Innovations and Future Trends in EPS Packaging

The evolution of packaging technology is rapid, and innovations in Expanded Polystyrene (EPS) reflect a dynamic market shift. Staying at the forefront of these innovations is critical for businesses looking for EPS packaging that combines performance with sustainability.

Driving Innovation Forward:

-

Advanced Material Formulations

- Researchers and engineers are constantly refining EPS composition to enhance thermal insulation packaging while preserving its lightweight advantage.

- Ongoing innovations result in higher impact resistance and improved moisture-resistant packaging properties.

-

Eco-Friendly Enhancements

- The latest EPS developments focus on boosting recyclability and reducing environmental footprints.

- Innovations in bio-based additives are making sustainable EPS packaging a tangible reality.

-

Smart Packaging Solutions

- Integrated technologies, such as sensors embedded into EPS for real-time monitoring of conditions, are transforming traditional packaging.

- Such solutions offer data-driven insights and enhance Protective foam packaging by alerting stakeholders to any transit issues.

Future Trends

-

Customization at Scale

- The trend towards personalized packaging experiences continues to expand. Enhanced manufacturing techniques enable more precise and efficient custom-cut EPS foam solutions.

- This trend supports a wide array of industries, from electronics to pharmaceuticals, by emphasizing product-specific protection.

-

Sustainable Production Practices

- With increasing regulatory focus on environmentally responsible materials, innovations ensure EPS remains compliant and eco-friendly.

- Advancements in recycling technology further cement Recyclable foam packaging as a key component of the circular economy.

-

Improved Design Flexibility

- Future EPS products will offer even greater adaptability, allowing for complex geometries and integrated features that drive down costs while improving product safety.

- Enhanced design methods will lead to more efficient use of materials in Lightweight packaging solutions.

At The Foam Company, we actively monitor these trends to integrate the most advanced EPS packaging solutions into our offerings. By combining industry-leading technology with practical insights, our innovative approach ensures that our products not only meet but exceed the evolving demands of the market. Our commitment to continuous improvement and research reinforces our position as forward-thinking EPS packaging suppliers dedicated to sustainable innovation and customer success.

Customer Success Stories & Industry Applications

Real-world results illuminate the true impact of effective packaging solutions. At The Foam Company, we take pride in sharing success stories that highlight the benefits of our expertly engineered EPS packaging. Our customers across varied industries have experienced firsthand the advantages of using our sustainable, protective, and versatile foam solutions.

Success in Multiple Industries

-

Electronics & High-Tech

- Clients in the electronics sector consistently report fewer product damages and enhanced transit efficiency thanks to our EPS for fragile items.

- Custom-made custom-cut EPS foam ensures precision fit and optimal protection for delicate instruments.

-

Food & Beverage

- Our food-grade EPS solutions have maintained the integrity of perishable items during long-haul shipping.

- Customers appreciate our lightweight packaging solutions that guarantee product freshness and safety.

-

Pharmaceutical & Medical

- Institutions have relied on our thermal insulation packaging to ensure vaccines and medicines arrive in optimal condition.

- EPS’s moisture-resistant properties reduce risk during transportation, reinforcing our reputation for reliable protective foam packaging.

-

Industrial & Construction

- Heavy equipment and sensitive industrial parts benefit from the robust shock absorption offered by our advanced EPS designs.

- Custom packaging configurations have led to significant decreases in breakages and damage-related costs.

Testimonials and Impact:

- Our partners often cite the high level of customization, quality, and cost efficiency delivered through our EPS packaging.

- Success stories reveal that precise, tailored solutions such as custom foam packaging help streamline operations, reduce waste, and enhance the overall customer experience.

Delivery of Excellence:

- Dedicated Support: Our expert team collaborates closely with customers to identify the optimal packaging design, ensuring each solution meets industry-specific requirements.

- Quality Assurance: Rigorous testing and quality control guarantee that every batch of EPS meets high standards for durability, insulation, and eco-friendliness.

By leveraging the full spectrum of our advanced EPS solutions, our customers continue to achieve operational excellence and market success. Their positive feedback fuels our drive to innovate and exceed expectations in every project.

Conclusion

Expanded Polystyrene (EPS) packaging gives you a tough, adaptable and sustainable way to tackle today’s shipping headaches. From our ready‑to‑go EPS sheets to precision custom‑cut pieces, The Foam Company backs every product with a focus on performance, the planet, and true customer care.

This blog has unpacked the essentials: how EPS absorbs shocks, maintains temperature control, and adapts across electronics, food, pharma, and heavy‑duty industrial freight. We’ve shared the custom options we offer, touched on the innovations steering tomorrow’s foam solutions, and highlighted success stories that show these benefits in action.

By refining our range around sustainability and exacting fit, we help you stay ahead of emerging demands while keeping costs under control. Choosing EPS means choosing reliable, eco‑smart protection that keeps your goods safe and puts your brand in a stronger light.

Thank you for taking the time to read our guide. For tailored advice, contact the specialist team at The Foam Company or explore our range online. We are ready to elevate your packaging with innovative, sustainable EPS solutions.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.