Polyethylene Foam Rolls - IXPE - Formshield

Description

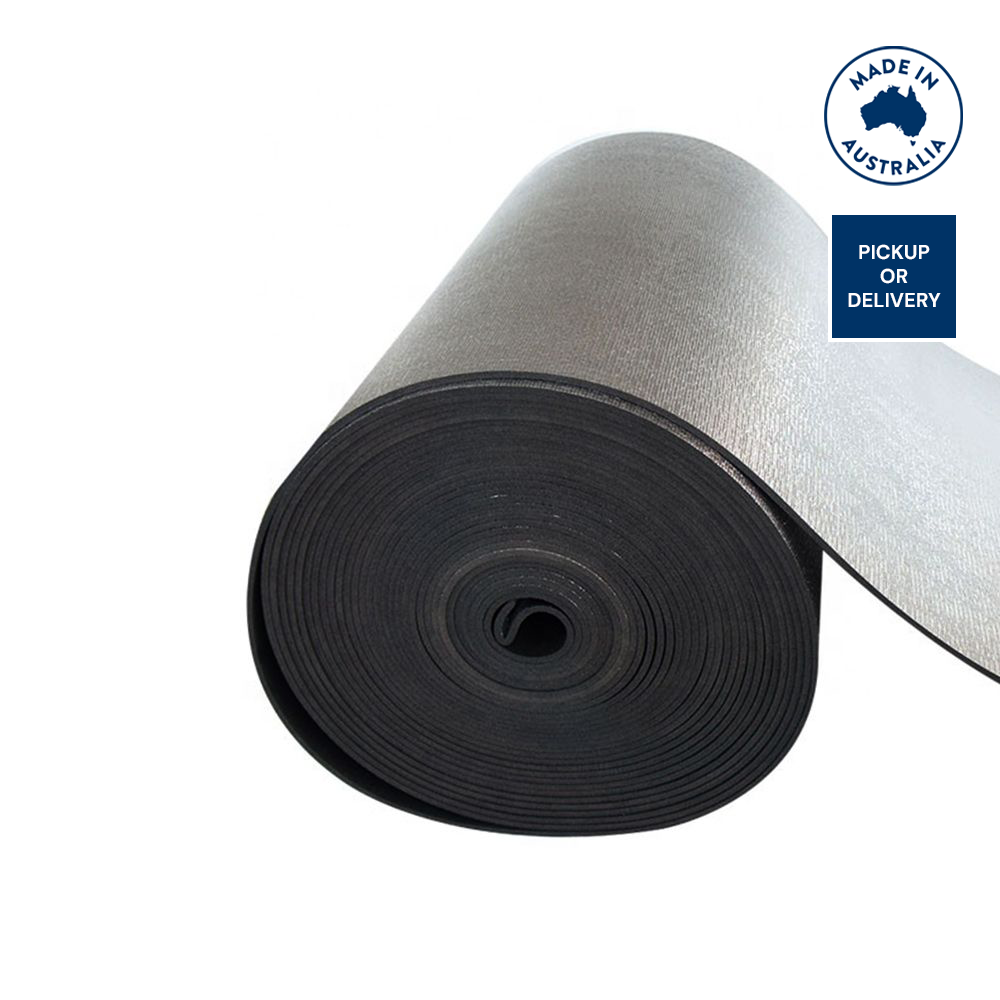

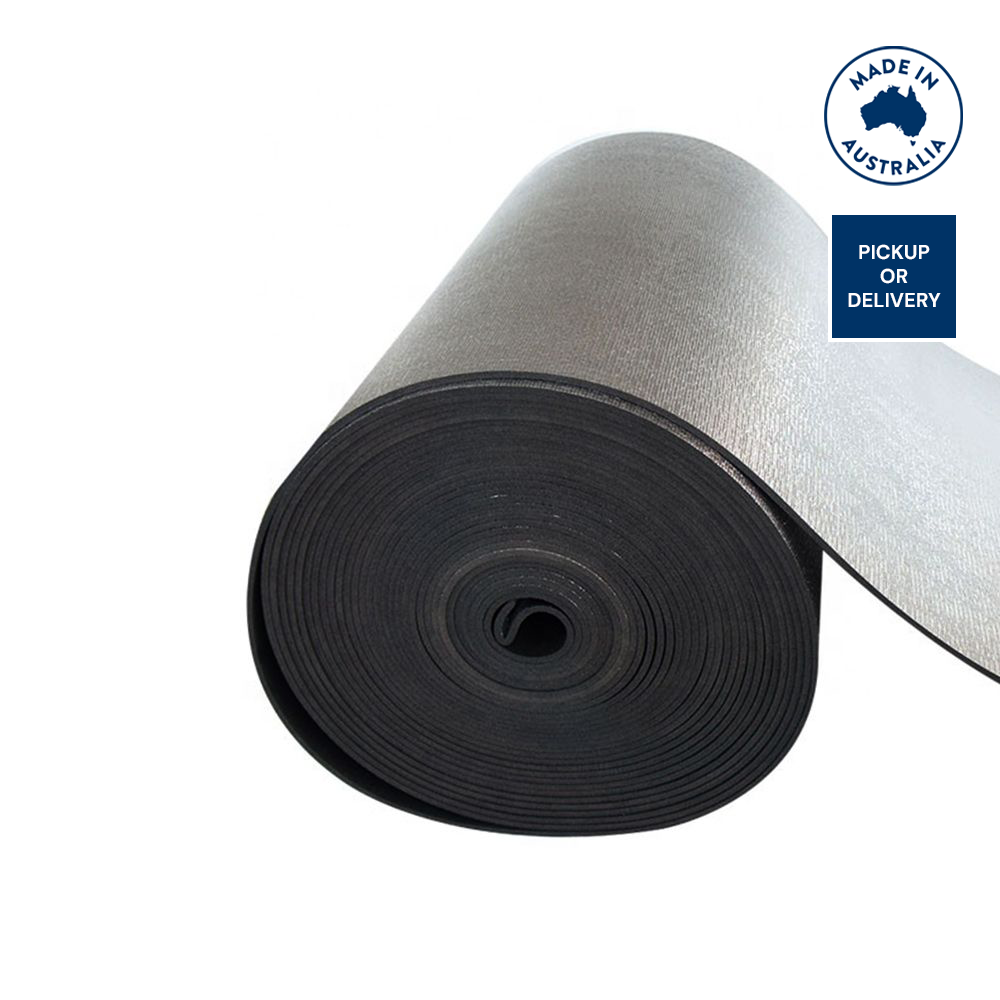

Used in a variety of applications in construction, industrial, automotive and marine industries. The rolls are 1000mm wide and available with or without a pressure sensitive adhesive backing in various foam thicknesses. With a low thermal conductivity, almost zero vapour permeability, fast and simple installation and trouble-free operation in a variety of internal and external environments. The material is flexible and compressible, and will not break or crack when used around curves or columns. The product is trouble-free and safe to handle, does not emit fibres, dust or other health hazards. It is easy to cut and drill on site and is the number one choice for sound and thermal insulation applications.

APPLICATIONS AND FEATURES

- Vibration dampening

- Foam seals and gaskets

- Concrete expansion joints

- Lining for air conditioning ducting

- Upholstery

- Wall panels

- Machine enclosures

- Impact absorption

- Gap-filling

- Packaging

More information

Shipping Estimate

Technical Data

Properties of Expanded Polystyrene (EPS):

Closed-Cell Lightweight Cellular Plastic

EPS is made up of tiny, closed-cell structures filled with air, making it lightweight yet strong. This structure provides excellent insulation and moisture resistance.

Flame/Fire Retardant

Many EPS products are manufactured with fire-retardant additives, making them self-extinguishing when exposed to flames. This improves safety, especially in construction and insulation applications.

Excellent Floatation Properties

Due to its closed-cell structure, EPS has exceptional buoyancy and is widely used in marine applications across Queensland, such as flotation devices, buoys, pontoons, and boat docks.

Shock Absorbing Properties

EPS is often used in protective packaging and cushioning due to its ability to absorb shocks and impacts, protecting fragile products during shipping and handling.

Low Environmental Impact

EPS is 100% recyclable and does not release harmful chemicals during its lifecycle. Additionally, its lightweight nature reduces fuel consumption during transportation, making it an eco-friendly choice in construction and packaging.

Benefits of Expanded Polystyrene (EPS):

Cost-Effective

EPS is affordable and widely available, making it a cost-effective material for insulation, construction, and packaging compared to alternatives like fiberglass or rigid polyurethane foam.

Easy to Use & Handle

Due to its lightweight nature, EPS sheets and blocks are easy to transport, cut, and shape, reducing labor costs and installation time.

Superior Thermal Insulation

EPS provides excellent thermal resistance (R-value), making it a preferred material for wall insulation, roofing, and flooring in buildings, helping reduce heating and cooling costs.

Water and Moisture Resistance

The closed-cell structure prevents water absorption, making EPS ideal for outdoor and underground applications, such as drainage systems, foundations, and flotation devices.

Versatile Applications

EPS is used across various industries, including construction, civil engineering, packaging, marine, signage, landscaping, and theming for movie sets. It can be custom-cut into different shapes and profiles, making it highly adaptable.

Durable & Long-Lasting

EPS does not rot, degrade, or break down over time, ensuring long-term performance in insulation and structural applications.

This product is rated 5.0 of 5.0 stars.

It has received 5 reviews.

HAVE ANY QUESTIONS OR ENQUIRIES ABOUT THIS PRODUCT?

ENQUIRY FORM

Phone: 1800 362 626 (1800 FOAM CO)

Email: sales@thefoamcompany.com.au

Hours: Mon-Fri: 8am to 5pm AEST, Sat-Sun: Closed

Order pickups: A limited number of products can be picked up direct from our multiple warehouses in each state. See relevant product pages, or contact us directly.

Our sales representatives will get in touch with you as soon as possible.